| PRODUCTS |

|

| |

| CARTRIDGE HEATERS |

| HIGH DENSITY CARTRIDGE HEATERS |

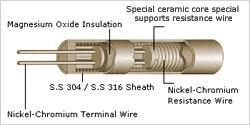

| Micro Electric Corporation High Watt Density Cartridge Heaters are manufactured with most advanced technology and quality raw materials, enables usage with high watts in small spaces and advanced manufacturing process ensures our heaters are vibration proof and thus ensures excellent reliability in heavy duty working conditions (Like Plastic Processing, Printing, Packaging and automobile industries where the heaters are subjected to heavy vibrations). The high performance is achieved by correct installation of the cartridge heaters. The perfect fitness of the heater in the hole facilitates good heat exchange between the surfaces of heater and mass to be heated thus increases the heater life and reduces energy loss. |

|

| Features |

- Sheathing material : SS 304 and SS 316.

- Available with inbuilt Thermocouple 'J' or 'K'.

- Maximum sheath temperature 800oC.

- Rugged & durable construction.

- Highly compacted construction improves heater life and reduces the effect of vibration and shock.

- Excellent heat transfer.

|

|

| Applications |

- Plastic processing machinery.

- Hot runner mould.

- Packaging machinery.

- Dies & moulds.

- Shoe machinery.

- Labeling machineries and a lot of other applications.

- Food processing machinery.

- Hot Stamping.

- Heating gases and liquids.

|

| Mounting Bore Clearance |

| The gap between the heater O.D and the bore I.D should be very close. |

| To determine Fit |

- Fit = Largest hole I.D - Min heater O.D

- Ex: Heater O.D = 12.5 mm (?± 0.06mm std. tolerance)

- Hole I.D = 12.6 mm (?± 0.02mm hole tolerance)

- Min heater O.D = 12.44 mm

- Largest hole I.D = 12.62 mm

- Fit = 12.62 - 12.44 = 0.18 mm (max permissible clearance)

|

| |

Refer Operating temperature Vs Watt density graph to

find max permissible clearance. |

| Dia |

mm |

6.5 |

8 |

10 |

12.5 |

16 |

19 |

25 |

| inch |

1/4 |

5/16 |

3/8 |

1/2 |

5/8 |

3/4 |

1 |

| |

|

|

|

|

|

|

|

|

| Length |

Min mm |

35 |

35 |

40 |

40 |

50 |

60 |

75 |

| Max mm |

250 |

250 |

500 |

500 |

1500 |

1500 |

1500 |

|

|

| ??Terminals |

- Fibre glass or Teflon wire crimped or welded to terminals.

replica watches

- Fibre glass wire with SS metal braiding.

- Wires protected with SS or GI flexible conduits.

- All wires are available in straight or right angle exit.

- Drawing or sample required for special type terminals.

|

| Top |

|

| |

| LOW DENSITY CARTRIDGE HEATERS |

| Micro Electric corporation Low Density Catridge Heaters are made of helically wound nickel chrome resistance wire evenly stretched and placed in ceramic insulators. The elment assembly is inserted into Brass/SS 304 tube. High grade MgO powder is filled in the remaining space inside the ceramic insulators to swiss replica watches

increase thermal conductivity, dielectric strength and heater life. |

|

| Features |

- Low watt density heaters are available in brass or SS 304 sheath.

- Medium & High watt density heaters are available in SS 304 sheath.

- Braided Wire, straight or right angle exit.

- Uniform surface temperatures.

- Flange type optional Braided wire.

- Max temp for SS tube 400oC, for Brass tube 200oC.

|

| Applications |

- Processing machinery.

- Injection and Blow Moulding.

- Hot runner bushings.??

- Packaging machinery.

- For fastening of turbine bolts.

- Extruders.??

- Hot plates, moulds & dies.

- Food processing machinery.

- Medical Equipments.

- Shoe Machinery.

|

| Mounting Bore |

| The inner diameter of the hole can be between 0.15mm and 0.30mm larger than the cartridge diameter. The lesser the clearance between the heater and the bore diameter, the longer will be its life. |

| Size |

- Diameter -??Min 8mm to Max 45mm.

- Length?? - Available in any desired length.

- Max watt density 3.5 watt/sq cm.

- For higher wattage and high temperature we recommend high watt density cartridge heaters.

|

| ??Terminals |

- Available in Teflon wire, fiberglass wire and nickel chromium wires. Insulated with ceramic beads or fiber glass sleeves.

- From Dia 22mm onwards, screw connections are available.

- Send drawing or samples for any specific configuration.

- Fibre glass or tefflonwire crimped or welded to terminals.

|

| When Ordering please Specify |

- Type of heater.

- Wattage and Voltage.

- Dia & length of the heater.

- Drawing for special type configuration.

|

| |

| We can manufacture and supply any intermediate diameter and length, Send drawing or sample for special size. |

| Top |

| |

| SPLIT TYPE CARTRIDGE HEATERS |

| Micro Electric Heaters, Split Type Cartridge Heaters are developed for high temperature application. Helically wound resistance coli is placed inside the tube filled with MgO powder and compacted for faster and efficient heat transfer. |

|

- Split-heaters expands to maximize heat transfer and contracts when cold for easy removal from bore.

- Ideal for use in oversized bores. Eliminates need for tight fits, tight tolerance bores.

- A single continuous heating coil ensures a uniform temperature profile. No sections to burn out as in conventional cartridge heaters.

|

| Features |

- Excellent heat transfer. ??????

- More clearance can be provided for inserting split type cartridge. Heaters??compared to standard conventional cartridge heaters.

- Can be inserted and removed easily. ??

- Longer life.

- Uniform heat transfer.

- Available in SS304 SS316 sheaths.

- Hot zone up to the tip of the element.

|

| Applications |

- Plastic Processing & Packaging Machinery.

- Injection & Blow Moulding.

- Extruders.

- Foundaries.

- For fastening of Turbine Bolts.

- Soldering pots.

|

| When ordering please specify |

- Dia & length of the heater.

- Wattage and voltage.

- Type of terminal.

- Drawing for special type configuration.

|

| |

| Available |

Dia: Mm |

6.5 |

8 |

10 |

12.5 |

14 |

16 |

19 |

| Length(mm) |

Min |

40 |

40 |

40 |

50 |

75 |

75 |

100 |

| Max |

500 |

600 |

900 |

1500 |

1500 |

1500 |

1500 |

|

|

| We can manufacture and supply any intermediate diameter and length, Send drawing or sample for special size. |

| Top |

|